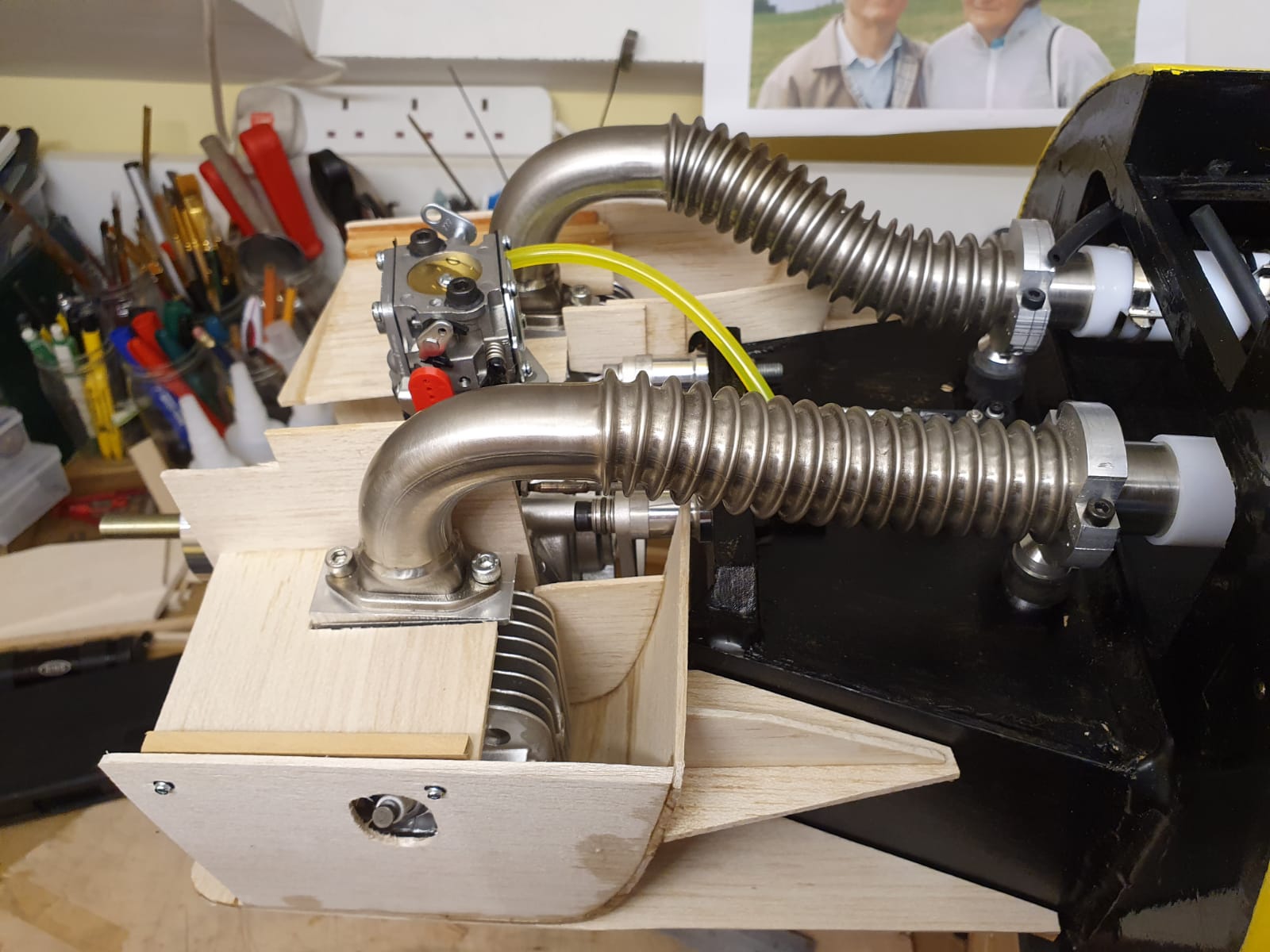

How I reshaped exhaust down pipes for my DLE120cc:

Items required:

- Suitable flat plate (Mounting plate)

- Spacing plates

- Blow torch

- Two x 4mm bolts

- Bench vice

- Drill, drill bites and taps

First drill and tap two holes in the centre of your mounting plate to secure the down pipe. Align spacing plates and scaffolding tube.

Heat the pipe and bend as necessary.

This may need to be done several times to achieve shape required.

Making additional angle flange plates to reduce the amount of bending for the down pipes

Items required:

- 5mm thick aluminium plate

- Milling machine and attachments or Hacksaw and files will do.

[URIS id=1604]

Mark and drill hole positions, flange sizes and porting holes.

Scribe a line at the angle needed on the side of the plate.

This will help with setting up the milling machine.

Once you have mounted your work piece, offer up the cutting tool to the scribe line.

The tool should run parallel with the line.

Take small cuts until you achieve the size required.

Mill out the porting holes or drill and file holes.

Cut out flange plates and dress down.

Then you hope it all fits. – Paul Taylor